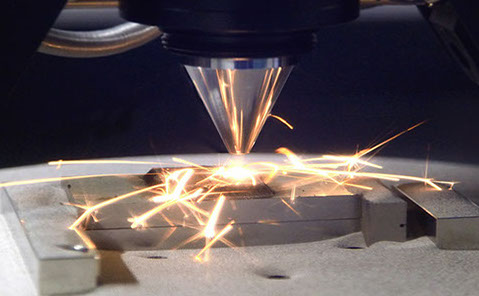

SLM Tecnology

Selective Laser Melting (SLM) is an additive technology that involves laser melting of metallic material, which is presents in a powder state, for the production of objects three-dimensional objects.

Discover Products

SLA Tecnology

Stereolithography (SLA) is an additive manufacturing technique that allows individual three-dimensional objects to be made by employing particular photosensitive resins solidified through a UV source.

Discover Products

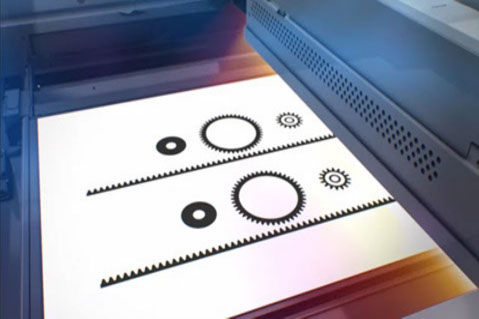

SLS Tecnology

Selective Laser Sintering (SLS) is an additive technology that involves. the laser sintering of plastic or metallic material, which is presents in a powder state, for the production of objects three-dimensional objects.

Discover Products

MJF Tecnology

MJF 3D printing is a powder bed fusion technology that uses a heat source to fuse particles within a build chamber filled with thermoplastic powder. The process, however, differs from SLS because Multi Jet Fusion does not use lasers, but rather an infrared energy source combined with a fusing agent to produce each layer of the part.

Discover products

LCD/DLP Tecnology

This technique works by an array of LEDs that light up on an LCD screen. The LCD screen consists of tiny pixels that are active or inactive, creating an image of each individual layer of the 3D object by letting UV light pass through them. High-resolution LCD screens offer advantages with regard to both printing speed and print quality.

Discover Products

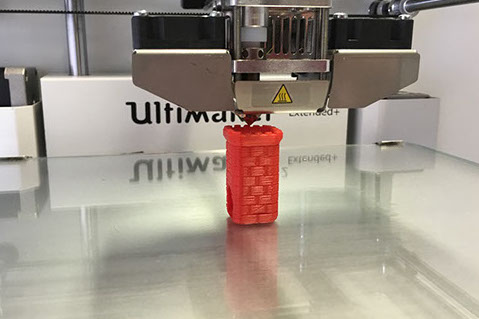

FDM Tecnology

FDM (Fused Deposition Modeling ) is a technology that involves a filament of material melted by an extruder that moves along the X and Y axes, depositing a layer of material on the printing plate.

Discovers Products

Contatct

info@zrise.it

+39 0825 1687016

Address

P.zza Vittorio Emanuele, 10

84084 - Fisciano (SA)

svg-crop-u147734.jpg?crc=34438611)