SLM PRINTERS

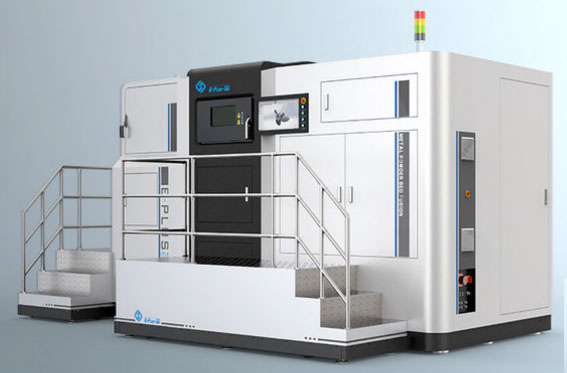

EP-M1250 Metal 3D Printer

Thanks to MPBF (Metal Powder Bed Fusion) technology and nine laser systems the EP-M1250 ensures high-efficiency production. The system can operate with various metal powders such as titanium, aluminum and nickel-based alloys, Maraging steel, stainless steel, cobalt chrome alloys and other materials. It is suitable for the direct production of large parts

Build volume 1250 x 1250 x 1350 mm

9 laser for maximun efficiency

Materials:

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M450H Metal 3D Printer

The new EP-M450H is a wonderful metal printer that makes it possible to produce reliable, high-quality large metal parts on an industrial scale, without the need for any tools.

Build volume 450 x 450 x 1080 mm

Optional: Dual laser system with a power of 2*500W

Materials:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M650 Metal 3D Printer

Using MPBF (Metal Powder Bed Fusion) technology and four laser systems, the EP-M650 ensures high-efficiency print production. The system can operate with various metal powders such as titanium, aluminum and nickel-based alloys, stainless steel, cobalt chrome alloys and other materials. It is suitable for the production of large parts with high precision.

Build volume 650 x 650 x 800 mm

Four lasers simultaneously print up to 120 cm³ with a 3,5 times increase in efficiency compared to a single laser system.

Materials:

Nickel Alloys

Titanium

Stainless Steel

Refractory

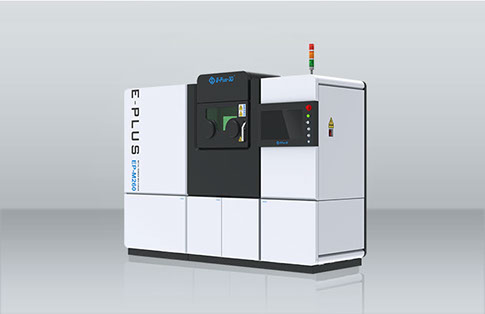

EP-M450 Metal 3D Printer

The fully open system makes the EP-M450 a very powerful tool for large-scale production, allowing our customers both to access different metal powders such as titanium, aluminum, nickel alloys, and stainless steel and to be able to change all parameters such as laser power. The EP-M450 aims to produce large parts due to its high performance and high precision.

Build volume 450 x 450 x 550 mm

Maximum building rate of 55 cm3/h

Materiali:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M400 Metal 3D Printer

The new EP-M400 is a wonderful metal printer that makes it possible to produce reliable, high-quality large metal parts on an industrial scale, without the need for any tools.It is available with a choice of single laser, dual laser, and four lasers.

Build Chamber Size 400 x 400 x 450 mm

Single/Dual/Quad laser optional

Materials:

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M300 Metal 3D Printer

EP-M300 is a wonderful metal printer that makes it possible to produce reliable, high-quality large metal parts on an industrial scale with an optional 500W/1000W single or dual laser, an ideal choice for large parts and efficient batch production.

Build volume 300 x 300 x 450 mm

500W/1000W single or dual laser optional

Materials:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M260 Metal 3D Printer

The EP-M260 is an industrial metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It can easily and quickly convert CAD data into high-performance metal parts with complex structure. The 3D printer is an ideal choice for medium-sized parts and small batch production.

Build volume 260 x 260 x 390 mm

Optional: 500W/1000W single or dual laser

Materials:

Case Hardening Steel

Titanium

Copper

Refractory

Aluminum

Cobalt Chrome

Maraging steel

Nickel Alloys

Stainless Steel

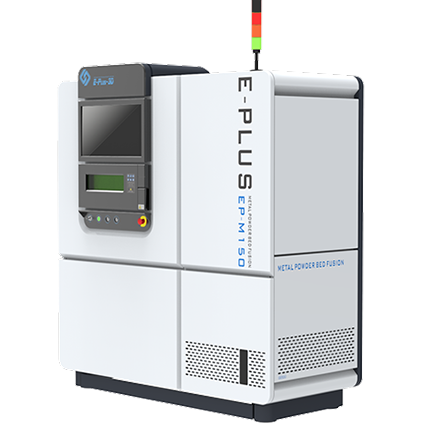

EP-M150 Pro Metal 3D Printer

EP-M150Pro adopts the patented MPBF™ (Metal Powder Bed Fusion) to produce parts with high performance, high precision and high level of detail. The machine is capable of optional single/double laser system and 200/500 W laser source to meet different production requirements.

Build volume 150 x 225 mm

The density of printed parts can reach nearly 100%

The Layer thickness can be up to 100 um

Materials:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

Nickel Alloys

Titanium

Stainless Steel

Refractory

EP-M150 Metal Dental 3D Printer

EP-M150 Metal Dental can professionally print metal dental crowns, bridges and brackets. The improved powder feeding and sieving system enables a high material utilization rate, with over 550 crowns printed with only 1 kg of powder.

Build volume 150 x 100 mm

Low operating costs: 550 dental crowns printed with only 1 kg of powder

Materials:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

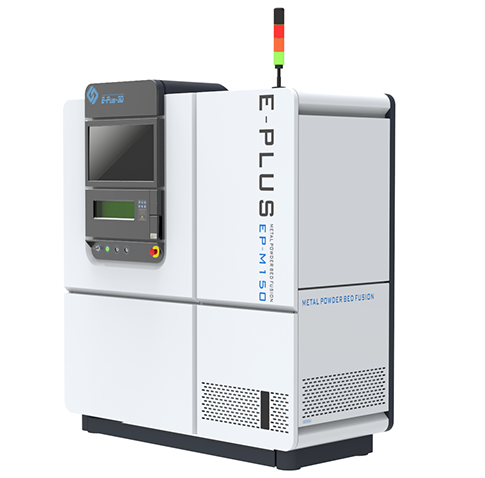

EP-M150 Metal 3D Printer

With Eplus3D MPBF™(Metal Powder Bed Fusion) technology, EP-M150 can professionally print complex 3D geometry data into high-performance metal 3D parts which are suitable for batch manufacturing of dental parts medical implants and material research centers to develop various metal powders with its open parameter platform.

Build volume 150 x 140 mm

Optimized structure design for easy maintenance

Materials:

Aluminum

Case Hardening Steel

Cobalt Chrome

Copper

Maraging steel

Nickel Alloys

Titanium

Stainless Steel

Refractory

Contatct

info@zrise.it

+39 0825 1687016

Address

P.zza Vittorio Emanuele, 10

84084 - Fisciano (SA)

svg-crop-u147734.jpg?crc=34438611)